Call us

Call us

How to recycle copper and aluminum from scrap radiators?

The scrap radiators are mainly composed of copper tube and aluminum foil scrap. The copper content of copper tubes can generally reach 97%, and the separation of copper and aluminum can be achieved from scrap radiators recycling machine.

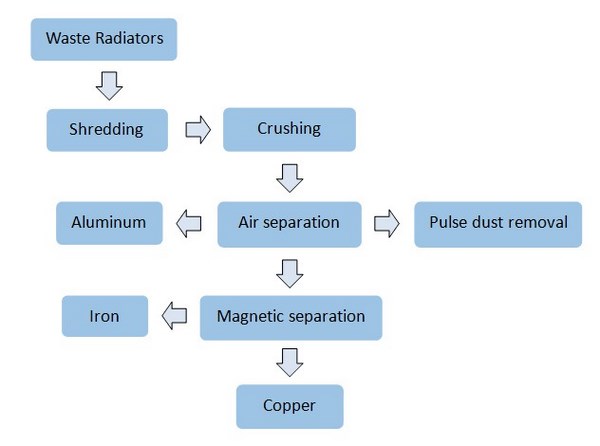

First, put the scrap radiators into a crushing main machine for rough crushing, and then enter a secondary crushing main machine for fine crushing, so that its aluminum, iron, copper and other fall off, and then by the strong magnetic roller and air separator to separate its aluminum, iron and copper. Pulse dust removal system is equipped in the process of crushing and separating, which can effectively solve the problem of dust discharge.

Working process of scrap radiators recycling machine

Working process of scrap radiators recycling machine

Compared with scrap radiators recycling machine, we DOING scrap radiators recycling machine has many advantages. It has lower metal loss and minimizes the times of material breakage. Ensure the separation of materials in large state, so as to reduce the production of metal powder and improve the recovery efficiency.

Scrap radiators crusher and separator uses dry crusher, high magnetic roller separator and air separator to crush and separate waste heat sinks. The whole process is carried out under negative pressure. This way separate copper and aluminum from scrap radiators which are difficult to disassemble manually or need too much labor cost to obtain renewable resources.

Scrap radiators recycling machine

DOING company’s environmental protection radiator recycling machine is green technology to separate copper and aluminum from scrap radiators. What’s more, radiator recycling machine is not only have a cheap price but also good quality. More details about radiator recycling machine can contact us we’ll provide you technical support accordingly.

Contact Us

- WhatsApp:

+86 150 3713 8562

- Email:

market@doinggroup.com

- Tel:

+86-150-3713-8562

- Phone:

+86-371-5677-1821

News

Project Case

FAQ

-

Air Conditioner Radiator - How to Separate Copper and Aluminium?

Air Conditioner Radiator - How to Separate Copper and Aluminium?

-

Three points you should know when choosing a radiator recycling machine

Three points you should know when choosing a radiator recycling machine

-

What are the characteristics of Doing radiator recycling machine?

What are the characteristics of Doing radiator recycling machine?

-

How to get copper out of radiator?

How to get copper out of radiator?

-

Which kinds of materials can be application to aluminum plastic recycling machine?

Which kinds of materials can be application to aluminum plastic recycling machine?